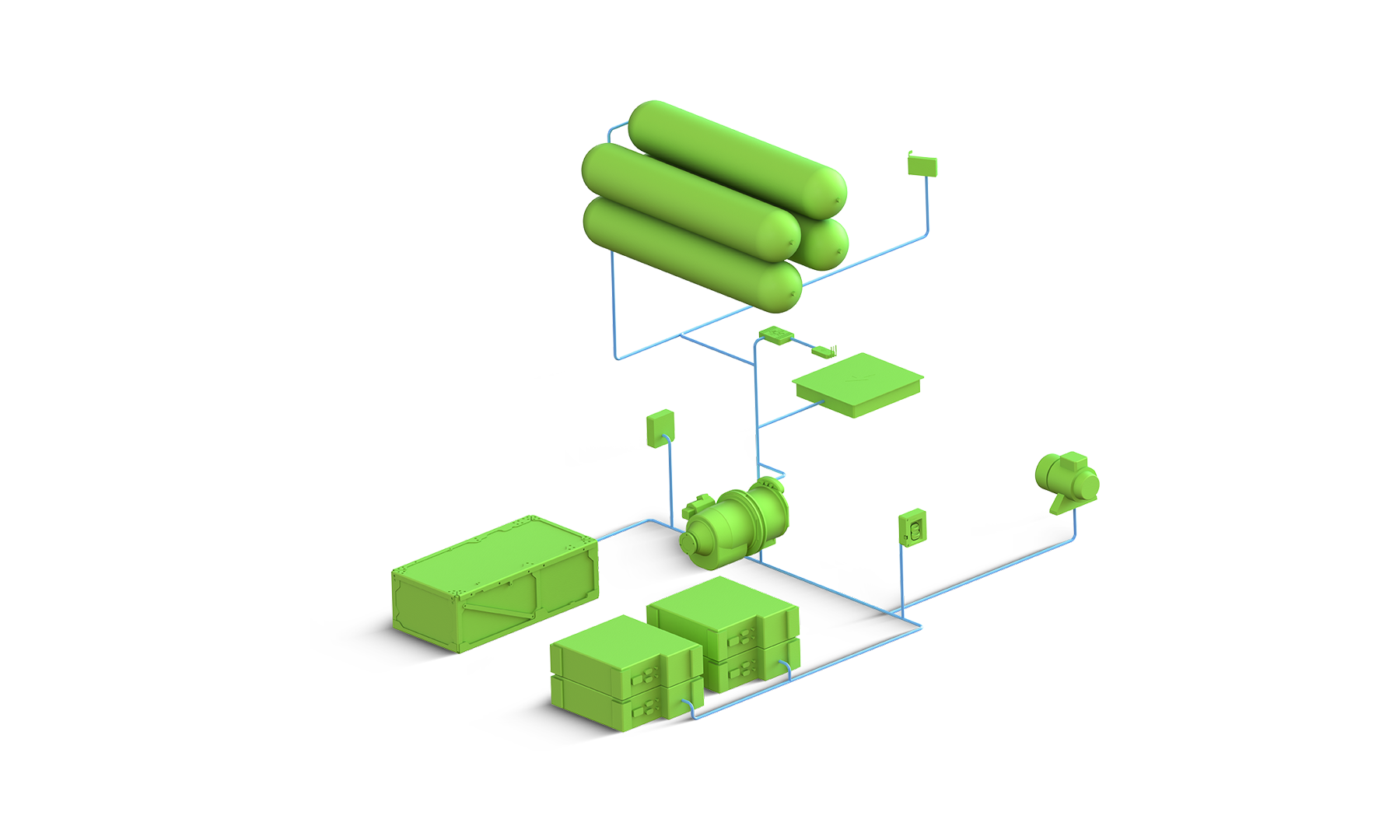

TECHNOLOGY NEUTRAL – BATTERY OR FUEL CELL.

Our modular drive system electrifies buses, trucks, and special vehicles. Both as a conversion kit for existing vehicles and as a drive kit for new vehicles, it is a fast, economical, and sustainable solution for the electrification of commercial vehicles. We offer the pepper kit in a purely battery-electric or fuel cell version.

HMI Display

An additional display is installed for the driver, which provides information on the vehicle status, range, battery and charging status, and other important system messages.

VCU

The VCU (Vehicle Control Unit) is the core element of pepper’s modular drive system. It integrates and controls all system components on a logical as well as functional level. The software is developed in-house and complies with the automotive industry’s highest standard for functional safety (ISO 26262). The pepper VCU easily allows the modular drive system to fit in all sorts of vehicles from different manufacturers.

Telematics Unit

Thanks to system-wide integration of the telematics unit used, a wide range of different data can be tracked. The current functions include vehicle tracking, online diagnosis, and the capture of live data about the vehicle state. Furthermore, over-the-air software updates will be available. Thanks to predictive analytical software from pepper’s technology partner TWAICE, the use of a digital battery twin increases the service life, efficiency, and sustainability of the batteries in use. Further useful value-added services for the digitalization of fleet management are already in development.

BJB

The Battery Junction Box (BJB) is pepper’s own development and serves as a “high voltage fuse box”. It is connected to battery (and optional fuel cell) and is being controlled by the VCU. Furthermore, the BJB is constantly monitoring the battery insulation and is crucial in case of an emergency if the system needs to be quickly discharged.

Auxiliary units

Other components of the kit include auxiliary units such as air compressors, servo pumps, air conditioning systems and hybrid auxiliary heaters, which are installed for purely electric or hydrogen-electric operation of the vehicle. An efficient control system, which takes over the interaction of these components, guarantees the most energy-efficient operation possible.

Charge Controller

The charge controller we use, is provided by chargebyte and serves both vehicle and charging infrastructure. It assures highest compatibility and can be directly integrated into the pepper modular drive system. Furthermore, it provides the option of using several charging sockets on vehicle side, which is highly practical for operation in depots. Close collaboration with market leader chargebyte allows fast development cycles and a glance into the future as the controller is fulfilling the ISO 15118 standard for bi-directional charging already today.

- Charging type: Type 2 CCS, DC charging

- Max. charging: up to 350 kW

- System voltage: 650 V

Electric Drive Train

Depending on the vehicle, different types of electric motors can be used, our portfolio of electric drive trains is growing steadily. For example, in the Mercedes-Benz Citaro city bus the AxTrax 140 electric portal axle from ZF is used, and in the Mercedes-Benz Actros MP3 truck the CeTrax central engine from ZF.

Battery

The pepper modular drive system uses a lithium-ion battery based on NMC technology (Nickel-Manganese-Cobalt). It comes in units of 60 kWh each, two of which can be seen on display. Minimum configuration for pure electric drivetrain is 120 kWh, scalable up to 720 kWh, depending on the vehicle and operation purpose. To charge a 240 kWh battery from 8% to 80% takes approx. 70mins, using a 150 kW charger.

H2 Tank System

For vehicles with fuel cell drive systems modular expandable hydrogen tank systems are used – one tanka has a capacity of 5 kg hydrogen. Refueling a tank system of 30 kg capacity takes approx. 10-15 minutes.

Hydrogen Fuel Cell

pepper is developing conversion kits for commercial vehicles to fuel cell drives, with fuel cells provided by Toyota. There are three conversion options:

- Battery-electric drive train with a fuel cell range extender for busses (range up to 400 km, shown here)

- Pure fuel cell drive train (without charge controller and plug and a smaller buffer battery; range up to 500 km for busses and 800 km for trucks)

with an energy consumption between 9 to 12 kg H2 / 100 km.

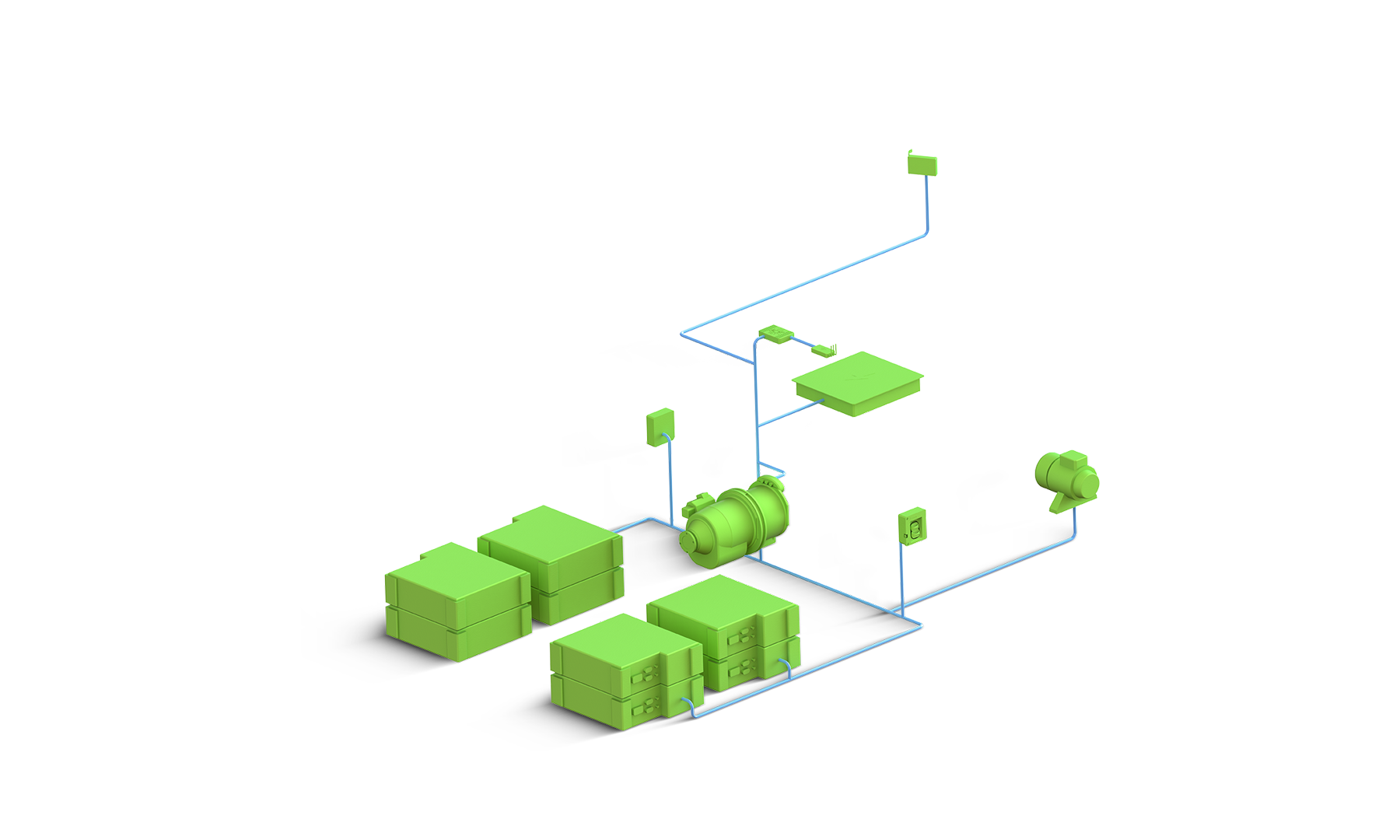

HMI Display

An additional display is installed for the driver, which provides information on the vehicle status, range, battery and charging status, and other important system messages.

VCU

The VCU (Vehicle Control Unit) is the core element of pepper’s modular drive system. It integrates and controls all system components on a logical as well as functional level. The software is developed in-house and complies with the automotive industry’s highest standard for functional safety (ISO 26262). The pepper VCU easily allows the modular drive system to fit in all sorts of vehicles from different manufacturers.

Telematics Unit

Thanks to system-wide integration of the telematics unit used, a wide range of different data can be tracked. The current functions include vehicle tracking, online diagnosis, and the capture of live data about the vehicle state. Furthermore, over-the-air software updates will be available. Thanks to predictive analytical software from pepper’s technology partner TWAICE, the use of a digital battery twin increases the service life, efficiency, and sustainability of the batteries in use. Further useful value-added services for the digitalization of fleet management are already in development.

BJB

The Battery Junction Box (BJB) is pepper’s own development and serves as a “high voltage fuse box”. It is connected to battery (and optional fuel cell) and is being controlled by the VCU. Furthermore, the BJB is constantly monitoring the battery insulation and is crucial in case of an emergency if the system needs to be quickly discharged.

Auxiliary units

Other components of the kit include auxiliary units such as air compressors, servo pumps, air conditioning systems and hybrid auxiliary heaters, which are installed for purely electric or hydrogen-electric operation of the vehicle. An efficient control system, which takes over the interaction of these components, guarantees the most energy-efficient operation possible.

Charge Controller

The charge controller we use, is provided by chargebyte and serves both vehicle and charging infrastructure. It assures highest compatibility and can be directly integrated into the pepper modular drive system. Furthermore, it provides the option of using several charging sockets on vehicle side, which is highly practical for operation in depots. Close collaboration with market leader chargebyte allows fast development cycles and a glance into the future as the controller is fulfilling the ISO 15118 standard for bi-directional charging already today.

- Charging type: Type 2 CCS, DC charging

- Max. charging: up to 350 kW

- System voltage: 650 V

Electric Drive Train

Depending on the vehicle, different types of electric motors can be used, our portfolio of electric drive trains is growing steadily. For example, in the Mercedes-Benz Citaro city bus the AxTrax 140 electric portal axle from ZF is used, and in the Mercedes-Benz Actros MP3 truck the CeTrax central engine from ZF.

Battery

The pepper modular drive system uses a lithium-ion battery based on NMC technology (Nickel-Manganese-Cobalt). It comes in units of 60 kWh each, two of which can be seen on display. Minimum configuration for pure electric drivetrain is 120 kWh, scalable up to 720 kWh, depending on the vehicle and operation purpose. To charge a 240 kWh battery from 8% to 80% takes approx. 70mins, using a 150 kW charger.

What characterizes our kit?

The kit consists of various components that are sourced from renowned suppliers or have been developed by pepper in house in accordance with the latest automotive safety standards. However, components alone are not a functional unit.

This requires the definition of the precise functions that the components must fulfill, including for example, safety standards, and suitable control software. The system architecture, which defines how components communicate and interact with each other, renders the kit functional.

All of this distinguishes the pepper Kit and makes it one of the most efficient e-drive systems on the market, which can be designed for virtually any type of commercial vehicle, from city buses to special vehicles with superstructures. Purely battery-electric or with fuel cell.

For whom is the kit suitable?

Order development

Analysis

Analysis of the vehicles to be converted for technical characteristics, TÜV inspection reports, analysis of subsequent requirements such as route lengths, route profiles, round-trip times, charging points, etc.

Planning

Detailed specification in terms of range, battery capacity, drivetrain, air-conditioning, and optional charging concept

Implementation

Conversion and commissioning of the vehicle in a partner workshop including TÜV vehicle approval

Operation

Support and advice during recommissioning with awareness training for workshop staff and planning of the necessary charging infrastructure

Equips our vehicles with valuable battery analysis capabilities.

Supplies original components for the powertrain of our vehicles.

Supplies our vehicles with free electricity via integrated solar panels.

Equip our vehicles with charge controllers.

Manufactures complete battery systems for our vehicles.

Equips our vehicles with valuable battery analysis capabilities.

Supplies original components for the powertrain of our vehicles.

Manufactures complete battery systems for our vehicles.

Supplies our vehicles with free electricity via integrated solar panels.

Equips our vehicles with charge controllers.

Contact us

If you would like to learn more about our electrification solutions, drop us a line!